Stringent cleanliness requirements in the manufacture of pharmaceutical products

These requirements also extend to production resources and tools. To ensure that goods conveyors are thoroughly cleaned with high quality and process reliability, an international pharmaceutical company has invested in a new cleaning system. In addition to task-specific cleaning media at the correct temperature, the system uses ideally coordinated ultrasonic components to achieve specified cleanliness levels quickly, efficiently and reliably.

The experts from Pace-Tec GmbH located in Furtwangen specialize in special machine construction for wet chemical production processes. They have developed a tailor-made solution that meets all requirements.

Fully automatic cleaning process in the clean room

During production, parts of pharmaceutical products are transported in the conveyors made of plastic, stainless steel and a combination thereof. The production resources and tools have to fulfill tough cleanliness requirements in order to rule out contamination of the products. The objective of the investment was improved cleaning quality and process reliability. The cleaning system was installed in a Grade D cleanroom in compliance with Good Manufacturing Practice guidelines. For reasons related to the previous cleaning processes, the media – ethanol and isopropanol – and the use of ultrasound were specified. The available space required high power density in a small area. Furthermore, given the prescribed solvents, the system had to be explosion-proof.

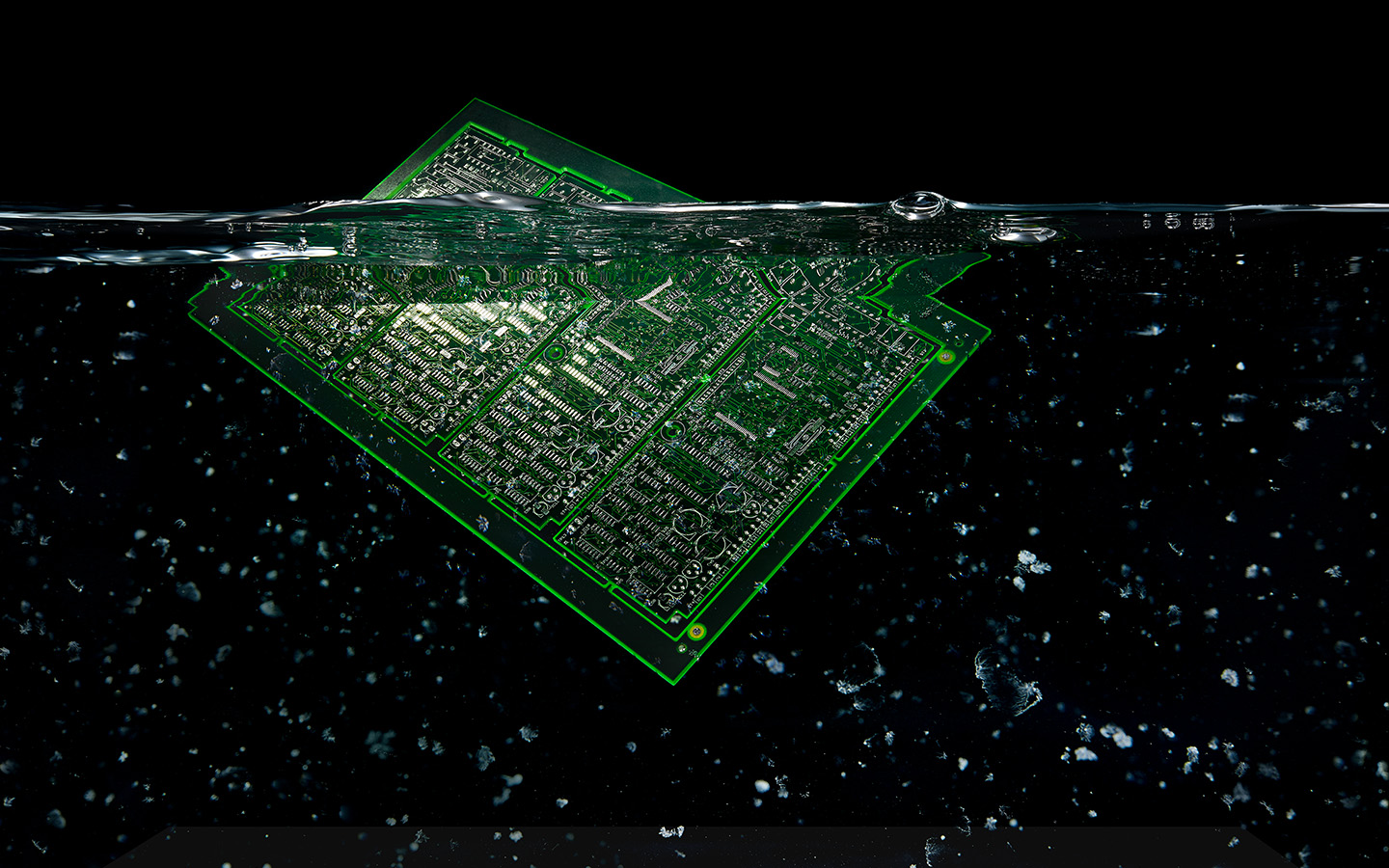

The Profinet interface of the Sonopower 3S generators allow to integrate ultrasound management in the Human-Machine Interface (HMI) of the system, which requires the exchange of high data volumes. It was also possible to simplify process data management over this interface.

Used solutions

Events

CLEAN SOLUTIONS FOR THE MANUFACTURING INDUSTRY

Optimum parts cleanliness: We'll show you how ultrasound technology optimizes industrial cleaning processes. Step by at our booth in Hall 10 B26!