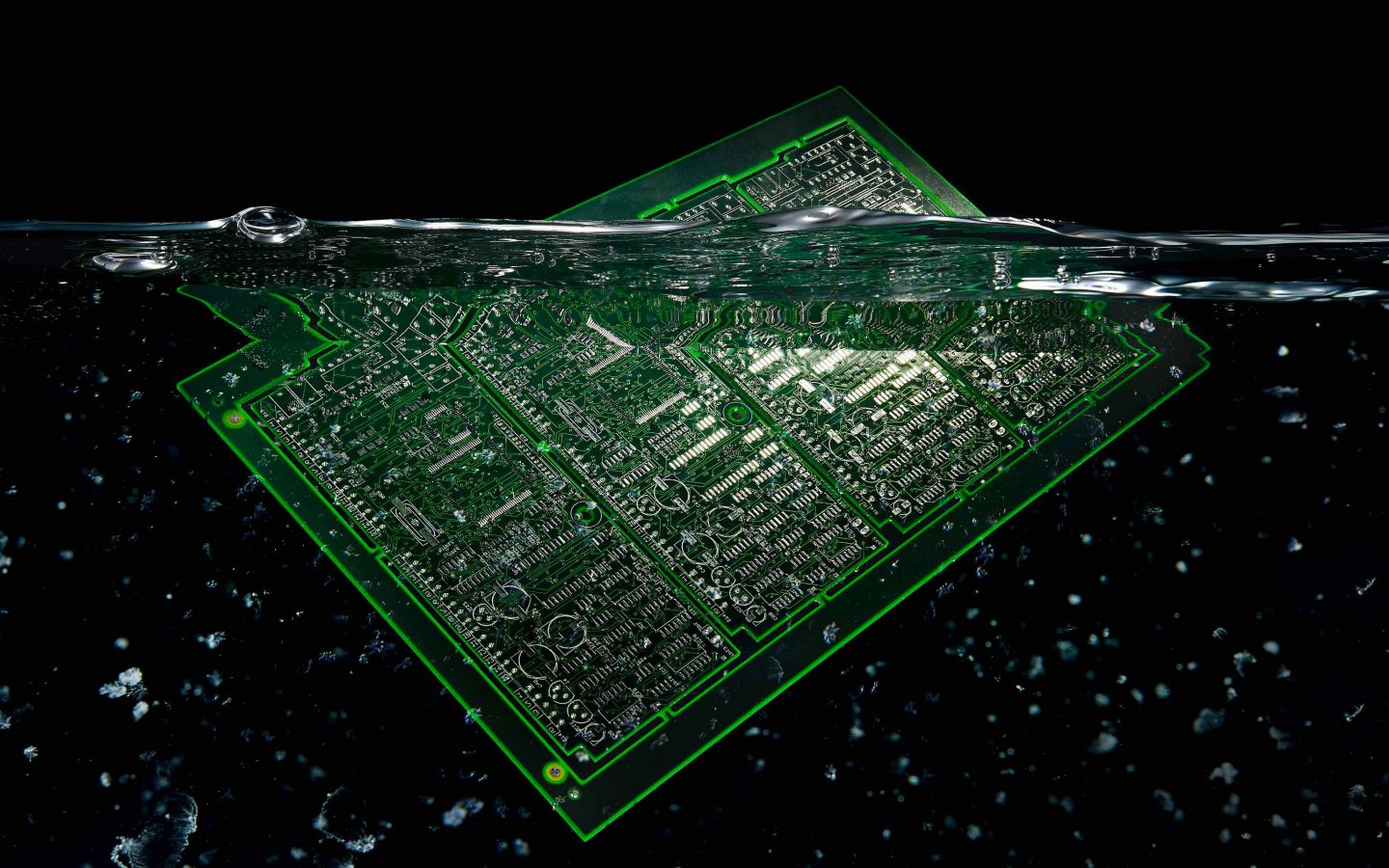

The Original – SONOPUSH® Rod Transducer

The SonoPush Rod Transducers can be operated with up to 2000 W power output. They are available in a range of lengths and models. The different models are suitable for a large variety of industrial cleaning processes.

Can be used in any cleaning system

Trouble-free conversion or retro-fitting with SonoPush Rod Transducers can be done in closed systems, chamber systems or open cleaning tanks. It’s possible to set up efficient cleaning processes in vacuum, under positive pressure and at high temperatures.

Heavy duty – for really difficult tasks

The patented SonoPush Mono HDT works very efficiently, including in continuous operation. Its intelligent cooling concept allows use in temperatures up to 95 °C and with demanding cycle times. The HDT model satisfies the highest cleanliness requirements with short cleaning cycles making high throughput possible.

Without competition. The SonoPush Rod Transducer from Weber Ultrasonics. Do you have questions about ultrasonic cleaning or our rod transducers? Please contact us. We’d be happy to help.

Robust and efficient

With the Sonopush rod transducers, your work will be efficient under all operating conditions. They stand up to enormous pressure and extreme temperatures. If your cleaning process demands a homogeneous sound field, the Sonopush rod transducer is the perfect choice.

Space-saving and high-performance tool

With its compact design, the Sonopush rod transducer permits a space-saving installation in your system. The transducer’s high cleaning performance ensures removal of particulate and film residue in a very short time. The rod transducers from Weber Ultrasonics have low maintenance requirements and high quality levels, thanks to their special materials and patented design.

Installation point

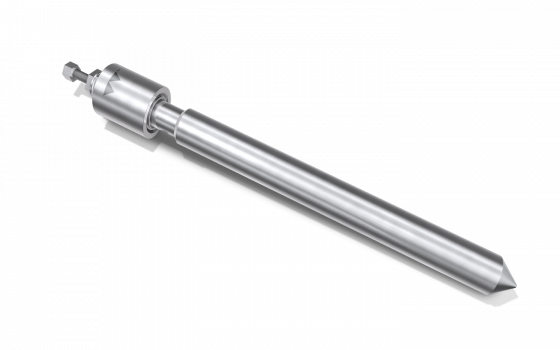

Thanks to its one-point attachment, the Sonopush Mono can be easily refitted to existing chambers. Your cleaning units run smoothly and require no time-consuming maintenance work.

Ultrasonic transducers

Unlike twin-head transducer systems, the Sonopush Mono works with just one transducer.

Design

The closed-body Sonopush Mono model with only one ultrasonic transducer increases operating reliability and decreases maintenance requirements. In development work the Finite Element Method (FEM) is used to simulate transducer operations to ensure optimum efficiency and a long service life.

Stainless steel, titanium aluminum, pure titanium

We produce the Sonopush Mono in a variety of materials to suit your application and the cleaning medium. Each of these material variants withstand the toughest conditions and offer you maximum durability.

The right model for any system

We offer the right rod transducer model and related generator for any cleaning requirement. Ranges of frequencies and performance classes are available, as are specific dimensions. Furthermore, rod transducers can be equipped with one or two mounting points – rod transducers can be used to outfit or retro-fit any system.

About our rod transducers

- Nearly indestructible: above-average service life

- For the toughest conditions: can be used in a vacuum, under high pressure or in continuous operation at temperatures up to 95 °C

- 360-degree effect: sound field with outstanding efficiency

- Built-in safety reduces maintenance and loss of production

- Space-saving design

SONOPUSH® MONO

Space-saving and efficient

The SonoPush Mono offers a larger radiating area than systems with two resonators with identical installation lengths. The design principle with only one active end makes the SonoPush Mono especially reliable. The risk of liquid penetrating the transducer is minimal.

Der SONOPUSH® MONO HDT

Heavy duty – for the toughest tasks

The patented SonoPush Mono HDT works very efficiently, even in continuous operation. Its intelligent cooling concept allows use at temperatures up to 95 °C and at high production rates. The HDT model satisfies the highest cleanliness requirements with shorter cleaning cycles and makes high throughput possible.

The SONOPUSH® Rod Transducer

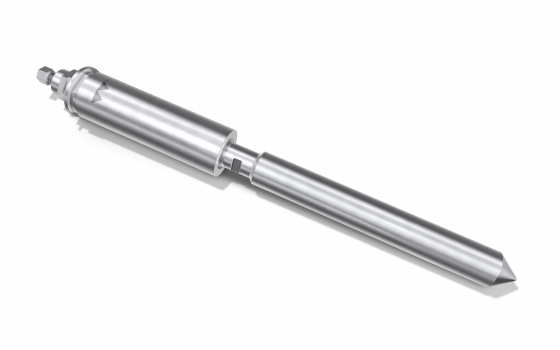

One driving head, two mounting points

The SonoPush is the first choice for outfitting systems build for transducers with two mounting points. Suspension at both ends offers a decisive advantage: Maximum length of the the SonoPush rod transducers. We produce these transducers with an active radiating length of up to 1287 mm.

Events

CLEAN SOLUTIONS FOR THE MANUFACTURING INDUSTRY

Optimum parts cleanliness: We'll show you how ultrasound technology optimizes industrial cleaning processes. Step by at our booth in Hall 10 B26!

Industrielle Anwendung von Ultraschall

Die industrielle Ultraschallreinigung kommt in vielen Anwendungsbereichen und Branchen zum Einsatz, beispielsweise in der Entfettung, Galvanik oder Oberflächentechnik bzw. Oberflächenbearbeitung. Die Ultraschalltechnik ermöglicht dabei außergewöhnliche Reinheitsgerade. In der Ultraschallreinigungstechnik wird die von Ultraschallgeneratoren erzeugte Energie über Ultraschallkonverter an sogenannte Ultraschallschwinger weitergegeben, dies können Stabschwinger, Plattenschwinger oder Tauchschwinger sein. Mit weiteren Ultraschallkomponenten sind ganz individuelle Anwendungen und Anlagen umsetzbar. Außerdem ermöglicht die Ultraschalltechnologie eine Reinigung von 25 kHz bis zum Megaschall.

Ultraschallschweißen

Auch das Ultraschallschweißen ermöglicht eine Vielzahl von Anwendungen. So lassen sich problemlos Ultraschallschweißsysteme für kontinuierliches Schweißen im Endlosbetrieb nutzen oder zum Kunststoffschweißen mit Ultraschall. Die von Ultraschallgeneratoren erzeugte Energie wird an sogenannte Sonotroden bzw. Ultraschallsonotroden weitergegeben und dann dem zu schweißenden Material zugeführt. Ganz individuell gefertigte Ultraschallkomponenten bieten darüber hinaus viele weitere Ultraschalllösungen.

Ultraschallschneiden

Für das Food Cutting, das Ultraschallfräsen und um Verbundwerkstoffe zu schneiden eignet sich das Ultraschallschneiden. Die von Ultraschallgeneratoren erzeugte Energie wird sogenannten Sonotroden bzw. Schneidsonotroden zugeführt, weitere Ultraschallkomponenten machen eine Vielzahl von kombinierten und zusätzlichen Anwendungen möglich.