Quality is worth the investment

In the production of face masks made from thermoplastic materials, processing with ultrasound scores highly in terms of efficiency, flexibility, and quality. Excellent system reliability, perfectly hygienic tools, and long-lasting material bonds are the prerequisite for producing high-grade products.

Soft and long-lasting

Great seam strength, smooth edges with no distortion, and the ability to weld even elastic materials with ease – that’s what ultrasound stands for. The fabric retains its soft, wearable structure, which is necessary especially in sensitive areas like the face.

Productive and efficient

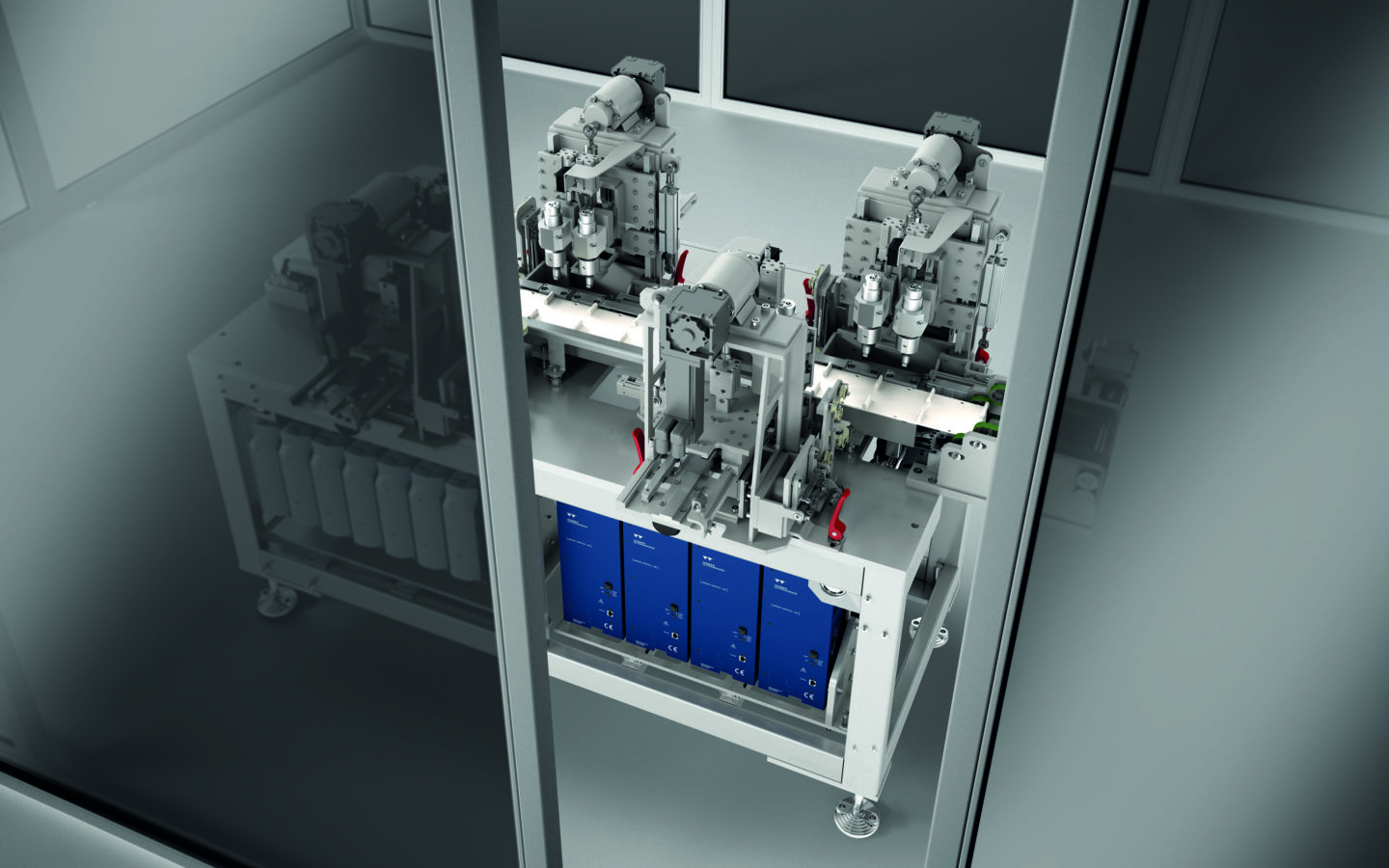

With large quantities especially, welding with ultrasound enables bonds that satisfy the highest quality standards. Our welding technology is Industry 4.0-compatible and can be optimally integrated into automated production lines, whether as components, manual workstations, or separate, fully automated production systems.

Benefits of Ultrasonic welding

- Hygienic, high-grade end products

- Great seam strength, smooth edges with no distortion

- Soft, wearable structure

- Industry 4.0-compatible

- Exact reproducibility

- Faster processing times

- Perfect system integrability

- High process reliability

- Particularly energy efficient