The revolutionary solution for pretreating and finishing textiles with ultrasound

Textiles, whether they are used for clothing or technical applications, are subject to various treatment and washing processes during manufacturing.

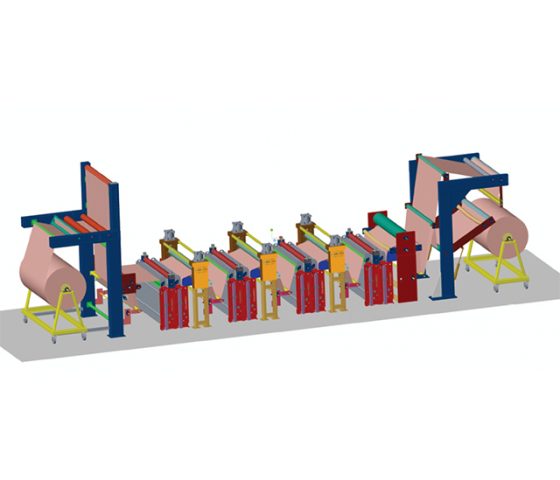

An innovative ultrasound solution, jointly developed by Weber Ultrasonics and Geratex Machinery Pvt. Ltd., enables a significant reduction in the volume of chemicals, water and energy required during treatment – while delivering better results in less time. This not only makes textile treatment more cost-efficient, it’s also more sustainable and saves resources.

Geratex Machinery Pvt. Ltd already put over 20 textile treatment machines in operation equipped with ultrasound technology in Europe, Asia, the USA and South America.

Benefits

- 30 % less chemicals and water consumption

- Up to 50 % energy & CO2-emission savings

- Reduction of process temperature from 95° to 60°C

- Shorter washing cycles

- High process reliability

- Optimum adjustment to different fabrics

Highly reliable, intuitive solution

The future-proof ultrasonic solution comprises a transducer to ensure the gentle, consistent treatment of fabric.

The fully digital SONOPOWER 3S ultrasound generator has been perfectly adapted for this. Equipped with a number of innovative technologies and a cutting-edge 32-bit processor, it’s able to carry out configurations automatically, monitor them continuously and keep them constant throughout. For example, the generator immediately detects the voltage and adapts to it. Any voltage fluctuations are automatically compensated within a range of +/- 10 per cent.

With a power output that can be modified in increments of 1%, the process can be easily adapted to the various requirements of textile treatment. These features ensure extremely easy handling and a high degree of process reliability.

Tailor-made for textile treatment

The specific needs of the textile industry were taken into consideration in the development of the ultrasound solution, which can also be integrated into existing machinery and processes.

These include the specific properties of the fabric that’s being treated, such as sensitivity, porosity and elasticity. The latter, in particular, is becoming more and more important due to the increasing use of elastic fabrics in textiles. In “stretchy” textiles, treatment with conventional machinery often leads to the formation of creases, which then leave a mark on the fabric.

This means the fabric must then be refinished or can only be offered as seconds. This is not a problem with ultrasonic treatment.

Perfect integration

Ultrasound technology enables the implementation of much more compact machinery. For example, ultrasound machines that allow for consecutive bleaching and mercerization can be implemented on a line of just 30 metres, instead of the usual 60 to 80 metres with traditional technology.

The ultrasonic unit for the washing process can also be installed directly into existing plant and machinery.

Let´s talk about sustainability

Ultrasound also boosts the cleaning power of the water used during washes in between the various treatments. As well as using around a third less textile auxiliaries and water, this results in a shorter wash time. Thanks to the adjusted cavitation energy, textiles can also be treated at significantly lower temperatures – at just 60°C instead of the normal 90 to 95°C. The resulting energy savings – up to 50 per cent – play a key role in reducing operating costs and conserving resources, as well as lowering CO2 emissions.

Another aspect is that sustainable textile treatment is becoming an increasingly crucial requirement in the purchasing decisions of fabric buyers.

Used solutions

Events

CLEAN SOLUTIONS FOR THE MANUFACTURING INDUSTRY

Optimum parts cleanliness: We'll show you how ultrasound technology optimizes industrial cleaning processes. Step by at our booth in Hall 10 B26!